By Ben Langlotz

|

August 12, 2020

|

Firearms, Intellectual Property Advice

|

0 Comments

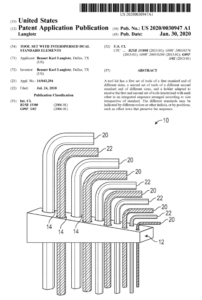

THE INVENTION I’M REALLY EXCITED ABOUT

The Only Allen Wrench Set I Use

The Only Allen Wrench Set I UseThe Problem

In engineering school, our product design class talked about “need finding.” We learned that just building cool stuff didn’t cut it in the real world – you had to be meeting the needs of some customers. Sometimes, those needs aren’t even realized – like having your entire music collection in your shirt pocket – but they are real once people are made aware of them.

A Dummy Sales Sheet

In this case, I got sick of the struggle to find the right hex wrench (“Allen” is a registered trademark but I’m baffled that the registration alleges use only going back to 1992, and suspect it could never become enforced as it has likely become generic like “escalator” and “zipper.”) I have more than a few sets, both SAE (fractional inch) and metric, and because there’s no way to tell what format the set is, I need both sets, and need to check both to guess which of the largest that fits of each feels like the better fit. By putting two sets together and arranging by size irrespective of format, the headache is eliminated, and I just need to find the largest one that fits.

The Patent Process

Knowing a good patent attorney, I immediately wrote up a patent. Now, when I do it for myself I can be a little sloppy, and while my patent drawings were adequate, they aren’t pretty. But I started with a full (non-provisional) patent application because I wanted to get the examination going. I don’t want to invest time and effort in raising the profile of the invention high enough to attract licensees, if there’s nothing to license. I’m letting the business and product development side sit until I get confident word on whether I can get a patent.

I gained some new sympathy for what my clients go through in the process. My office can’t get too emotional about every patent we work on or we’d go insane. We care but keep calm. We inventors aren’t like that – it’s a deeply emotional and personal experience. I recall getting the routine notice from my patent paralegal that I’d received the first examination by the patent examiner. Now, this is a really big deal in the process because it’s the milestone when we see whether the case looks good, or like a disaster. I almost went nuts when I saw that it took my staff FOUR DAYS(!) after it was received by us to get it to me. Four days!

Which was my reminder that we always want to give our clients as speedy communication as reasonably possible. Lesson learned. And four days isn’t that slow.

I scoured through the examination and saw that all claims were rejected. That’s OK, and typical for round one. What I really cared about was whether the cited prior art used to reject the claims was killer, or not. I was relieved to see that the examiner hadn’t found anything that made me worried, and was just citing tool holders that held both sets, maybe side by side, but with no relation between the sizes of tool from one set to those of the other. They weren’t arranged by size.

So, I rapidly scheduled a phone conference with the examiner. I’m used to all the examiners in the firearms group and have a dossier on each of their styles and preferences but had never worked with the examiner from the tool group. He turned out to be a good listener, and finally understood my explanation that my patent was for the arrangement of different formats/standards by size irrespective of format. He said now that he understood that he wanted to do more searching, and it might take a few months. That was October 2019. When I had heard nothing in three months, I contacted him and he said, “I’m too busy for a search – just file a response explaining what you told me.” Grrr…I just lost three months in the process needlessly. Since then I’m STILL awaiting his to look at my response that ought to be good enough to grant the patent. We sent an inquiry letter a couple months ago and got a grumpy voice message telling us to be patient.

So when your patent application is taking longer than expected, believe me that I sympathize more than ever.

Invest Big Bucks in Foreign Rights?

I recognize that patents are a big business investment, and I’m fortunate to be able to file them on a whim for only the U.S. Patent and Trademark Office filing fee and some of my spare time to prepare. But foreign protection is another matter – lots of filing fees, and legal bills from foreign law firms – no “friends and family discount”.

I wouldn’t have been optimistic enough to invest in foreign rights except that I got a very encouraging “maybe” from a client potentially interested in selling tools using my concept (see if you can guess from the back page which tool-seller might be the one I’d most want to have selling my stuff).

My published patent application

When foreign rights are a possibility, rule number 1 is “shut up.” Anything I posted on social media would be considered an international publication and kill potential foreign rights. Sort of. There’s a grace period of one year by treaty that lets you file foreign that much later, but I was too cheap for that. I wanted to delay more, until just before my patent published 18 months after filing. The added six months meant I absorbed the minor risk that someone invented the same thing and filed before I did in some other country, but I just wanted to put off the investment until I had a clearer view of the patentability question from the US examiner (which the first action gave me).

My Free Facebook Patent Search

Once the US application published, the cat was out of the bag, and I trumpeted it on my Facebook page that includes thousands of industry people who know a thing or two about tools. My ulterior motive was to get some free patent searching. You see, even if I had “good news” from the US examiner, I always wanted to find the kind of bad news that could endanger my patent during enforcement or licensing diligence, so I could deal with it in the patent examination and inoculate my patent against a later challenge. A harder road to a stronger patent. I’m doing the same thing in this very newsletter to an even larger audience – I’ll be grateful if you send me “bad news.”

My wish was granted when a respected gun designer and friend who sold his company to one of my clients chimed in with some links to tool sets that make me nearly have a heart attack. At first glance I thought I was sunk by the hex key holder blocks that held both metric and SAE in an apparently graduated row, but it turned out that on careful examination of web images that some of the tool location were NOT in sequence by size. They were arranged to neatly alternate metric and fractional! The company wanted to sell the block to store either their fat-handled metric wrenches OR their fat-handled fractional wrenches in nice evenly spaced rows. They didn’t care that some holes were out of the size sequence. I realized that I was apparently the only one who had thought of this head-slapping simple configuration and might still get a good patent. I immediately submitted the new reference to the examiner to ensure that he considered it and any patent he granted was inoculated against it.

All’s Well on the Foreign Front

Days ago as I wrote this, I got good news on the foreign filing. It’s essentially the same patent application examined by a different examiner in a different Office, by almost the same standards for patentability. As expected even in good-news cases all claims were rejected. But I was thrilled to see that the publication they based the rejection on was a set with a holder that held two different wrench formats in separate rows, with the tools alternating (like fingers alternating prayerfully). They were intermixed, in an alternating sequence, but there was no evidence that they were all arranged by size. In fact, there is no normal set of fraction and metric that avoids the occasional instance where two tools of one format are sized between adjacent tools of the other format (for example between the 3mm and 4mm hex wrench sizes are 1/8”, 9/64”, and 5/32”).

Alternating the tools is neat, tidy, and beneficial, but entirely inconsistent with and contrary to the nifty usability benefits of my invention. And that’s how obviousness arguments are won: if we can show that what the examiner proposes is an “obvious” change to render an invention unpatentable, we can overcome the rejection by showing that the change would ruin the desired benefits of that product. Win.

What’s really nice (hopefully) is that the busy/stubborn/nervous US patent examiner will now get news that another patent examiner said (or soon will say) that it’s patentable, so the US guy can go to his boss and say “the foreign examiner didn’t find anything either, so maybe we should let this one be granted.” It could well give him some confidence and cover against his uncertainties about granting a patent on such a simple-sounding invention. I hope.

How to Make a Fortune on the Internet?

OK, so if I get a patent, will I be like the dog who chases cars and then finally catches one? What next? I have a day job I like so I’m not looking to retire, and I don’t have time to start and run a tool company. Here’s the plan – maybe some reader can help. Thanks to the generous mentoring of a senior executive at a client who knows this stuff, here’s how I’m told to get royalties from big box stores: Make the product. Sell it. Only then do I go to the Lowe’s buyers with the idea that they could hang a third rack of hex keys in the tool aisle. They don’t care about good ideas, they like to see a real product that they can get a sample of, and that they see selling. I could sell on Amazon, eBay, and on a website, and easily fulfill shipments myself. There’ll be little (no) traffic at first, but at least I won’t care about profitability. The point isn’t to turn a profit but to generate interest from big companies that will sell tons of them and write me royalty checks.

I’ll produce enough initially to fulfill some orders, give away to friends, and most importantly, to send to every tool blogger and reviewer

thirsting for something new to write about (and link to Amazon for sales referral commissions). I don’t even care if they say something like “great idea, but poorly executed.” That’s because I just want the big buyers to take interest, not to sell my own.

But I do need a product. I can source L wrenches, and need to make a holder block, and hire someone (maybe from a client connection) to assemble – not that anyone in this industry has slack capacity to outsource these days. That shouldn’t be hard but it’s a little project I won’t start until I have allowed claims. I’m waiting for some industry friend to connect me with a fairly-priced consultant who can take some existing wrench holders, scan or caliper for hole dimensions, then jiggle things around in CAD to get my sequence of sizes, and a cheap aluminum tool for low volume production. Ideally, I’d have wrenches specially made, because invariably the metric tools that are the right size aren’t the right length compared to the other set so you don’t get that nice smooth “organ pipe” graduations of length that the cover photo is photoshopped to show. But the early sales and reviews can be from existing tools, and the licensees can resolve the length details with their suppliers.

Meanwhile I’ll have to cover the branding strategy later. Hopefully along with some good news.

Prediction: The SHOT Show WILL be cancelled.

Next month I’ll reveal the eight reasons why I’m so sure.